NUS scientists develop new liquid-based tactile sensors

SINGAPORE — It is thin, lightweight and flexible enough to act as “e-skins” to monitor a person’s skin condition, or be applied to a person’s skin to deliver the right dose of drugs at a touch.

SINGAPORE — It is thin, lightweight and flexible enough to act as “e-skins” to monitor a person’s skin condition, or be applied to a person’s skin to deliver the right dose of drugs at a touch.

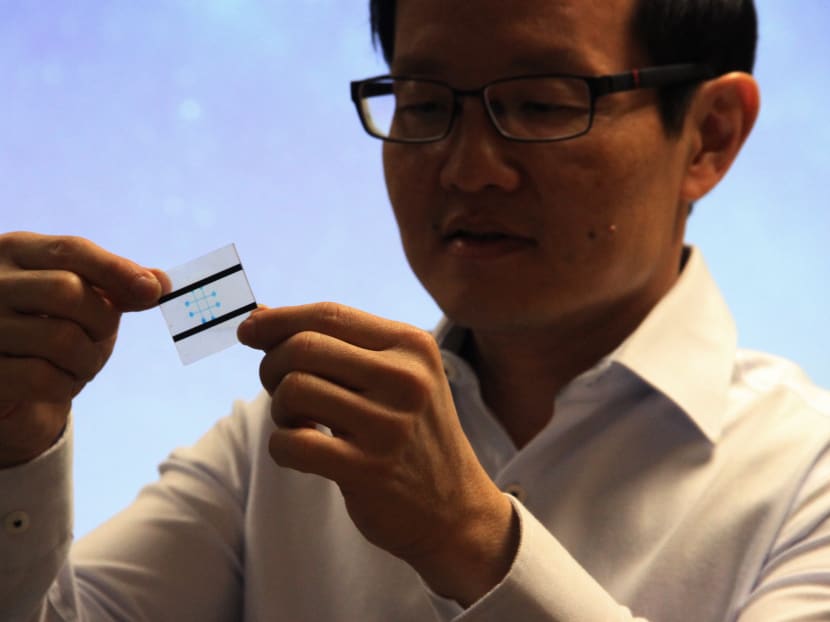

National University of Singapore (NUS) scientists have created a liquid-based tactile sensor, which involves the use of nanomaterial — such as graphene oxide — suspended in liquid, and can detect changes in temperature, force — as light as 0.7g — vibrations and hydration.

Conventional tactile sensors are typically made in solid-state form, making them rigid and bulky. Existing liquid-based sensors typically require the use of pneumatics, which makes them inconvenient to use.

The new first-of-its-kind microfluidic sensor, on the other hand, developed by a team of scientists from NUS’ Faculty of Engineering, is small, flexible and durable. It can be used for a variety of applications, including soft robotics and prosthetics, said Professor Lim Chwee Teck, who led the team.

“For example, people who have lost their hand or ability to touch, we can have sensors like this to mount of their fingertips. When pressed, they can create signals that can be routed to the brain to tell the user that they’re holding or touching something,” he said at a media briefing today (Sept 23).

Coupled with microneedles, the sensor can be made into a skin patch that administers drugs such as insulin painlessly and conveniently. Users can apply the patch onto their skin and press onto the patch to administer the drug when needed.

E-skins made with this sensor could be useful to cosmetic companies in product development. “So we can have the patients apply (moisturiser) and put the sensors over the skin to measure the condition of the skin, and time how long the moisturiser effect will last, for example,” said Prof Lim.

The sensor took about nine months to develop, a relatively short time as the department had already been working with microfluidics for eight years. The team took care to use materials that are non-toxic and safe. The technology is also cost-effective and more affordable than available conventional technology.

However, the team has yet to find a way for the sensor to function on its own as it lacks its own power source. They are currently working with other departments to make this possible.

A patent for this sensor was filed earlier this year. “With the rapid advancement of healthcare and biomedical technologies as well as consumer electronics, we are optimistic about new possibilities to commercialise our invention,” said Prof Lim.