New mega-facilities to treat 40% of S’pore’s waste by 2027

SINGAPORE — Within the next decade, a new waste management facility and a water reclamation plant co-located in western Singapore will be able to treat about 40 per cent of the total used water and solid waste here, with the facility generating enough energy to power more than 400,000 four-room Housing and Development Board flats.

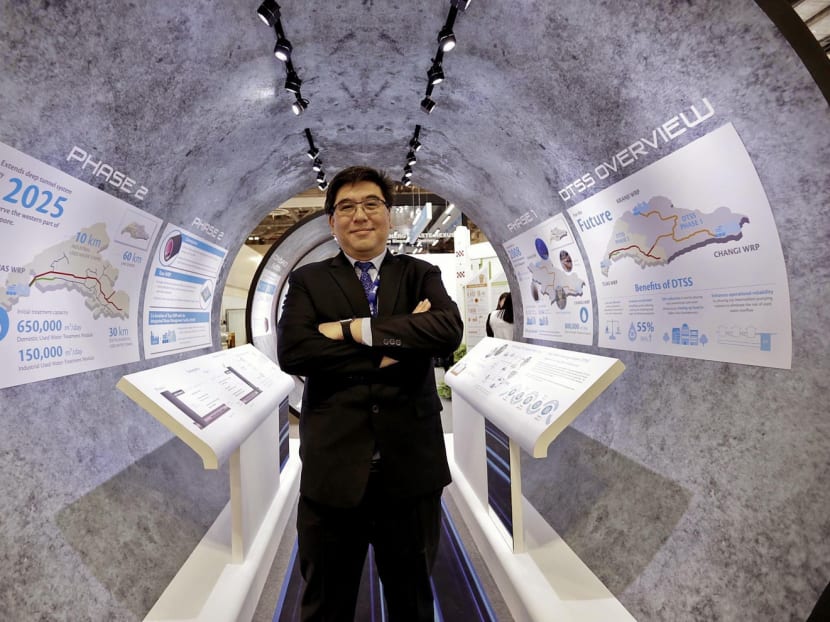

Director of DTSS Phase 2, Yong Wei Hin showing the plans involved in the construction of the new reclamation plant. Photo: Wee Teck Hian

SINGAPORE — Within the next decade, a new waste management facility and a water reclamation plant co-located in western Singapore will be able to treat about 40 per cent of the total used water and solid waste here, with the facility generating enough energy to power more than 400,000 four-room Housing and Development Board flats.

The Tuas Water Reclamation Plant (WRP) will be part of the Deep Tunnel Sewerage System (DTSS), a “superhighway” for managing used water, where the deep tunnel sewers will convey used water by gravity to the various centralised water reclamation plants. The system will reduce the land taken up by used water infrastructure by 50 per cent.

Details of the Integrated Waste Management Facility (IWMF) and the WRP, as well as the DTSS, were shared as the authorities announced that they would be calling for tenders from this year onwards.

National water agency PUB will be calling for consultancy and construction tenders for the various project components of DTSS Phase 2 in stages from the third quarter of this year. The projects include project engineering services for the design of Tuas WRP and the link sewers, among others.

Meanwhile, the National Environment Agency will be calling for tenders for project management, the supervision of construction works and the commissioning of the IWMF, among other tenders.

Estimated to cost S$3 billion, the IWMF at full capacity will be able to incinerate 5,800 tonnes of solid waste each day. Last year, Singapore generated 7.67 million tonnes of waste. Of this, about 38 per cent or 7,886 tonnes of waste each day was incinerated at the four existing waste-to-energy plants each day.

The first phase of the facility will be ready in 2022 and fully completed by early 2027. It is also expected to replace two of the existing waste-to-energy plants — Tuas Incineration Plant and Senoko Waste-to-Energy Plant — which are nearing the end of their lifespan.

It will also be able to process various waste streams: Incinerable waste, household recyclables, food waste as well as the dewatered sludge from the new Tuas WRP.

About 2,000GWh of electricity will be generated through its treatment processes, of which 10 per cent will be used to power both the facility and the plant, making them energy self-sufficient. The rest will be supplied back into the grid.

At present, the existing waste-to-energy plants generate enough energy to meet up to three per cent of Singapore’s total electricity demand. Singapore’s current water reclamation plants are not yet self-sufficient in energy.

Meanwhile, the new Tuas WRP will be able to treat about 800,000 cubic metres of used water a day, or about 40 per cent of the total used water generated. It can treat both domestic and industrial used water separately.

The plant is expected to be completed by 2025. The NEWater factory will then be integrated into the plant for large-scale water-recycling. This is done through membrane bioreactor technology that will streamline the used water and NEWater treatment processes.

With the completion of DTSS Phase 2 — estimated to cost some S$6.5 billion — the existing water reclamation plants at Ulu Pandan and Jurong, as well as the intermediate pumping stations, will be phased out.

With the IWMF and the Tuas WRP located on the same site, there will also be improvements in various aspects of the treatment processes. For instance, food waste from the IWMF can be co-digested with the used water sludge to increase the yield of biogas.

The biogas can then be used to improve the overall plant thermal efficiency of the facility, where more energy can be derived from every tonne of waste that is being processed.

Water treated at the plant can also be used for the facility’s processes, such as for use in the wet flue gas treatment system to get clean air emissions, as well as in the wet cooling tower to cool down the facility’s turbine exhaust and improve plant efficiency.